The Different Types of Damage ESD Can Cause to Electronics

Modern-day manufacturing can create a lot of harmful static electricity. While static electricity can be helpful for various uses, such as touchscreen devices, it is an unfortunate side effect of most modern manufacturing processes, and ESD can be detrimental to your products without proper countermeasures.

What is ESD?

ESD’s full name is electrostatic discharge. It is when electrons are transferred between two non-conducting surfaces when rubbed together.

Everything we touch creates a small electrical charge that can be turned into static electricity. We’ve all had a shock from a door handle or when shaking hands with someone, but electrostatic discharge is a far stronger shock. ESD is most commonly when a human body comes in contact with an electronic device, and a surge of static electricity is discharged.

This may sound like a harmless result, but an ESD surge can be over several thousand volts. This excess electricity can cause internal components to malfunction or break entirely.

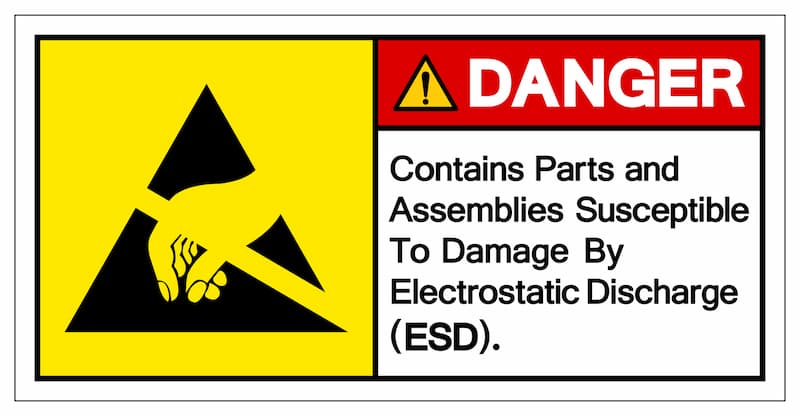

ESD is a hazard to the electronic industry and should be prevented wherever possible. In addition, appropriate industrial static control should be implemented in the form of ESD countermeasures in any environment when working with delicate electronics.

Different Types Of ESD

Not all ESD damage is the same, and there are two main consequences of an ESD surge, catastrophic failure and upset failure.

Catastrophic failure is disastrous for any electronic component. A direct failure will damage the part so that it won’t function correctly. Whilst this failure can easily be found in product testing but will require the component replacing. A latent catastrophic failure is more challenging to detect due to it weakening the product. This weakness can lead to further damage over time and a subsequent catastrophic failure.

Upset failure is a minor problem but a problem nonetheless. The ESD causes a current flow error that doesn’t cause total failure but can cause long-term malfunctions.

Why is ESD Harmful?

Why is ESD Harmful?

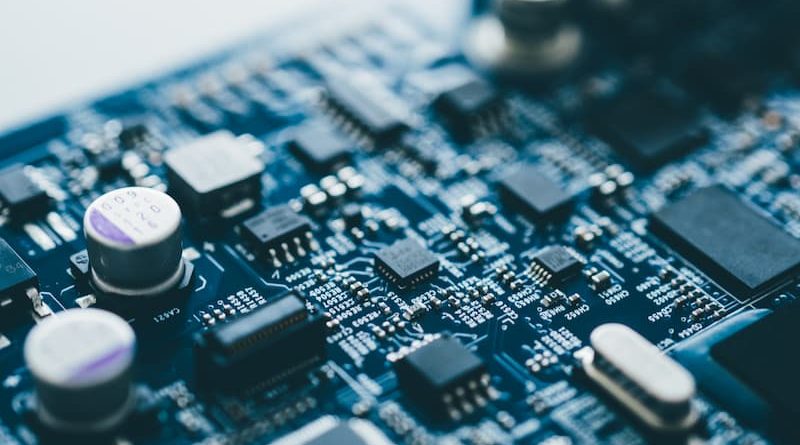

ESD can destroy sensitive components and erase or alter magnetically saved media such as hard drives or DVD data. In industrial environments, ESD can even spark flames that lead to explosions. As a result, the electronics industry suffers significantly from ESD damage every year, with roughly £40 billion in losses incurred due to ESD hazards.

ESD can happen at various seemingly harmful locations when using electronic devices.

- USB ports

- Output terminals

- Board connectors

Any locations with a physical connection to the device’s inner workings are potential conduits for ESD to cause damage.

How Can ESD Affect Your Business?

Without effective ESD prevention, you put your sensitive apparatus at high risk of damage, and any damage to your manufactured components will cost your business money. Fortunately, there are many different static elimination products readily available to prevent electrostatic discharge, such as our Contamination Control Mat. Our practical mats consist of 30 layers of environmentally friendly, water-borne acrylic adhesive.

These mats are highly effective for contamination removal. Once one layer is used up, you can simply peel it off and dispose of it, making them vital for cleanroom environments.

How To Get Proper ESD Protection?

How To Get Proper ESD Protection?

- Grounding

- Isolation

- Prevention

These are the three basic principles of effective ESD control.

Grounding is the means of draining the current static charge in your body safely to the ground. Wrist straps and personal grounding devices are helpful to achieve this goal. Your strap must be always in contact with your skin and grounded to the same ground as your static workstation.

Packing your assemblies in conductive materials during storage is a way to isolate your components. This is officially known as a Faraday cage and can be as simple as a metallic bag.

You can take many different preventative measures to prevent ESD from harming your products. The goal is to create a protected workspace to work with delicate electronic components safely.

ESD Straps are a fantastic ESD countermeasure. Products like our Anti Static Wrist Strap or our Anti-Static Heel Straps are durable whilst being lightweight so as not to hinder the technician wearing them. Suitable for use in cleanroom environments, these tools are a safe, reliable and cost-effective way to dissipate static electricity and prevent ESD instantly.

An additional helpful device to prevent ESD is a TVS Diode. This handy little device can be installed at these points vulnerable to ESD and protect semiconductor components from these high-voltage transients. Their full name is a Transient Voltage Suppression Diode, and essentially, they can let the electrical discharge ground itself without damaging any parts.

Adaptable ESD Solutions

Adaptable ESD Solutions

Ioniser-Pro specialises in static elimination equipment, and we pride ourselves in offering a wide range of Anti-Static Equipment. We have assisted a wide range of manufacturers in various industries and sectors in ensuring their ESD countermeasures are the best they can be.

If you have any questions about preventing ESD from harming your business, please contact us through our enquiry form or call us on 01937586987, and one of our expert team members will be happy to answer all your questions.

Why is ESD Harmful?

Why is ESD Harmful? How To Get Proper ESD Protection?

How To Get Proper ESD Protection? Adaptable ESD Solutions

Adaptable ESD Solutions