Customer satisfaction is hugely important to us. Here is what some of our current clients had to say about the Ioniser-Pro.

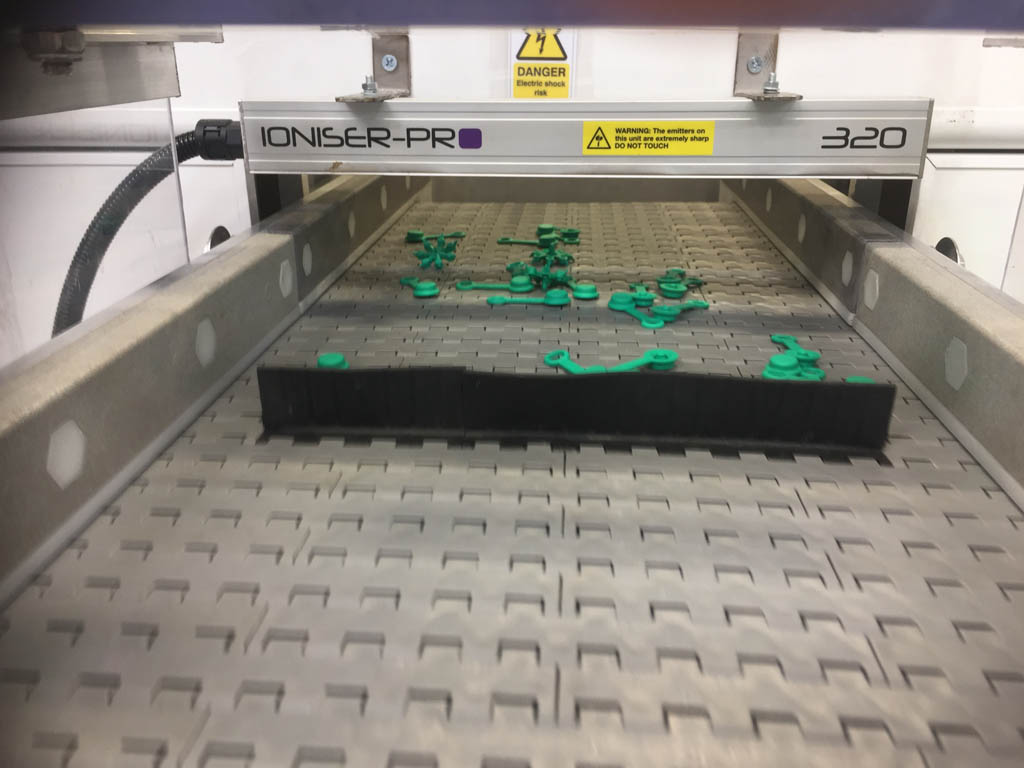

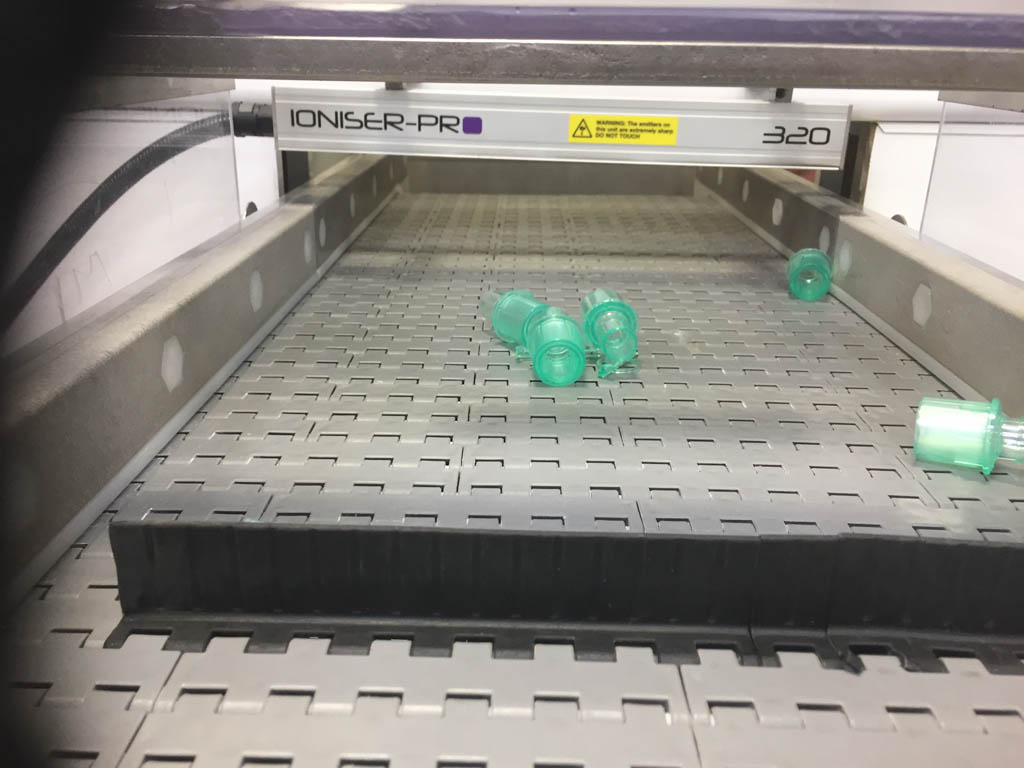

Each year our factory in Guernsey moulds 80 million plastic components for critical care medical products. Unfortunately for some of our operators working where the moulded parts are ejected, were prone to painful static shocks from time to time. Over the years we had tried to find a robust solution and finally resolved this last year, when we installed the Ioniser-Pro-320 from GSM Valtech Industries Ltd. Since installation there has not been a single incident of static shocks.

Throughout my 30+ years career there have a very few things that have really made a significant improvement to the screen and digital printing processes. These static eliminators are all the way at the top of that list. They are costs effective, easily installed with minimal expertise.

The improvements are immediately seen by significantly reducing the print issues associated with surface static charges. I first deployed these in the business critical printing processes through the business units.

Since then, and because of the low price, I have now run these out over the whole of the screen and digital print lines with huge benefits almost immediately. Waste has dropped such that the next phase will be funded by the savings from the first phase. You will need to look after the tips on the bars and its essential to make sure you use the cleaning packs, this will not only extend the life of the bars but it will ensure they operate at peak performance. In our UV printing clean rooms you can taste the difference, the air is dead.

This allows the room to remain at 99% operational readiness because these units keep the room free from charged dust particles. Any particles that do get in are neutralised and drop to the floor for the automatic robot vacuum cleaner to mop up in the early hours. Truly a simple product that really works.